Narendra Modi stadium of India found its way being the largest stadium in the world. It happens to be a renovated project, which was envisioned to be built as the largest in the world. The renovation started in the year 2017 and was completed by 2020 after which it became a fully functional stadium. This stadium is managed and administered by the Gujarat Cricket Association. This reconstructed stadium was the vision of Indian Prime Minister Shri Narendra Modi which came to life in 3 years. This was inaugurated on 24th February 2020. It can accommodate up to 11,000 cricket enthusiasts at a single time. The plan consists of an Olympic size pool, three practice grounds, dressing rooms, an indoor cricket academy, and 76 corporate boxes.

Under IGBC’s ‘Green new building rating system’, this stadium has got a gold rating. Another takeaway from this was the cost. For the quality and size of the whole plan, it cost around $102 million which is quite off-center.

The construction was under the contract of Larsen and Toubro (L&T). Apart from it being the biggest stadium, it is also popular for its state of art architectural design. The structural design of the stadium is done excellently. It is created on three tiers for different events. Structural engineer Walter P Moore has conceptualized the whole plan and created the most remarkable roof system.

Why Narendra Modi Stadium is the most influential project?

Project management institute has named Narendra Modi stadium to be amongst the most influential projects. Apart from it being the largest stadium, there are other factors attached as well that make it one of the most influential projects of 2020. It is the true symbol of architectural importance. It is said to be an innovative and captivating project that has been able to move forward despite the pandemic situation.

The stadium is a project designed by Populous. They serve Master Planning, Architecture, Interior Design, Landscape Design, and Wayfinding. Along with this one, Populous designed, Tottenham Hotspur stadium of London has also been ranked in the list of most influential projects.

Senior Principal of Populous has said

“It’s fantastic to see two of our projects recognized amongst so many important and intriguing 2020 initiatives. It shows the importance of architecture in our social fabric, even in a world with social distance.”

The managing director of Populous has stated that

“It is gratifying and humbling to see our work recognized alongside initiatives such as the Nightingale Hospital in London and the European Green Deal. This year has laid bare the necessity of sport and other live events in our communities. There is the immense joy that they bring and is loaded with quality to inspire us. In what continues to be an incredibly difficult situation for the area, we are continuously working with clubs and stadium operators regarding the safe return of fans to the seats, to once again bring us the precious moments of achievement and celebration that we enjoy so much.”

India is a country filled with cricket enthusiasts. It is a game that unites the whole country as one. And for obvious reasons holds a special place in all the hearts. With a grand project like this, it has been another milestone in the history of cricket that has left its fans all the more excited. The stadium is an open stadium with a panoramic 360° view that is made in a round shape. Any spectator seating anywhere in the stand gets an uninterrupted view of the entire field. This enables greater impact on the spectators by adding better visual experience and better sound effects as well.

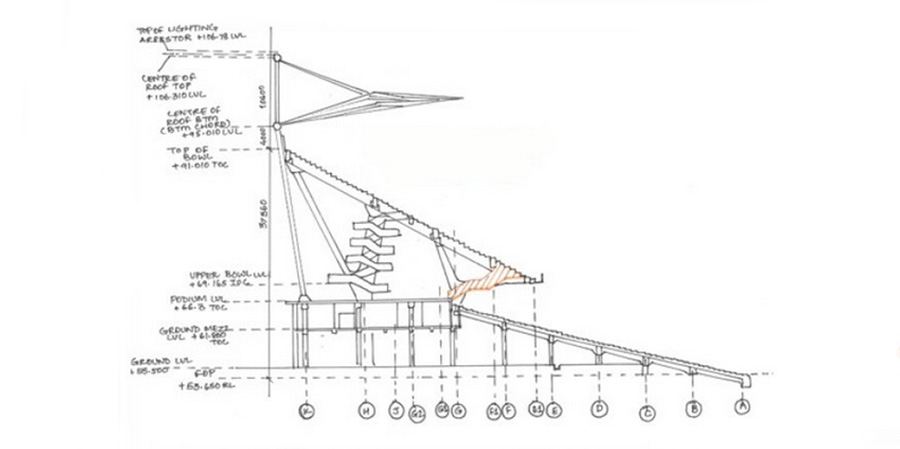

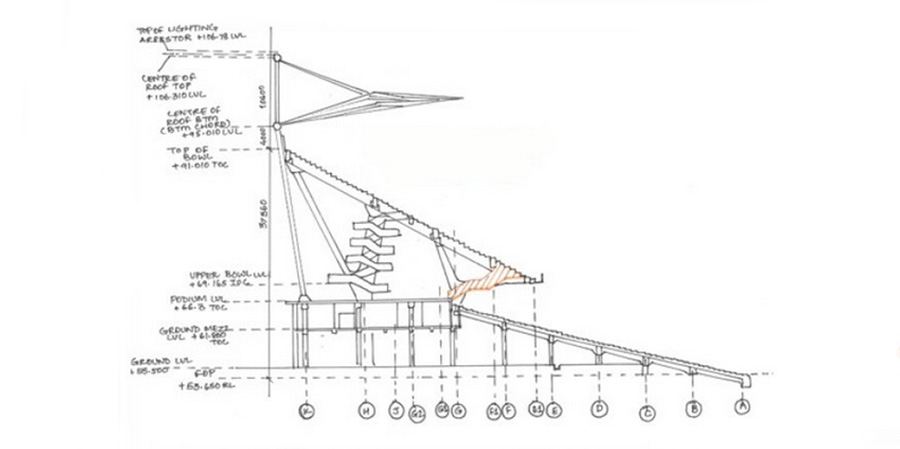

Roof structure and design

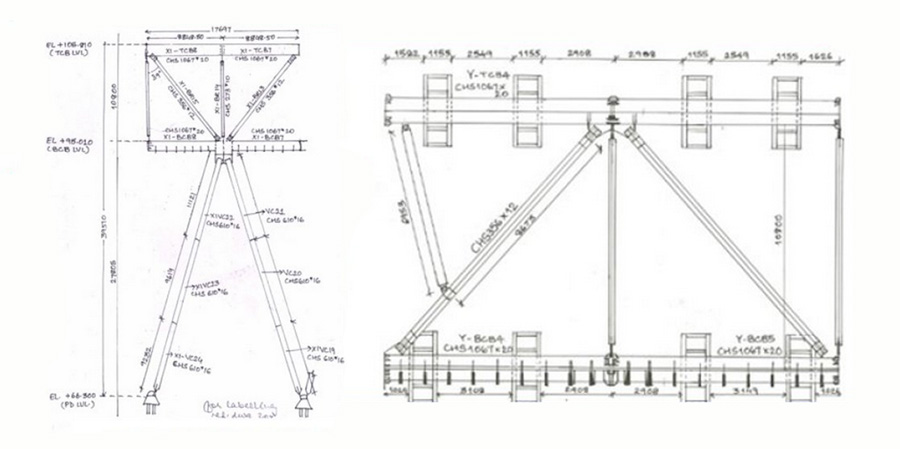

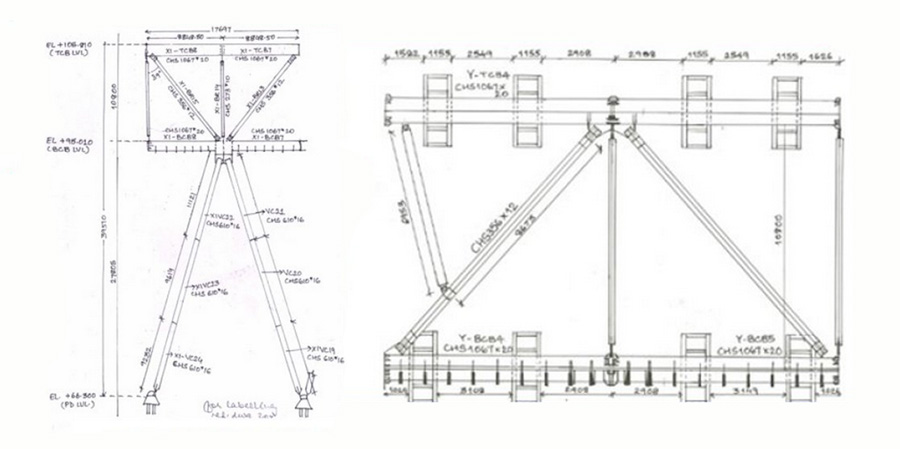

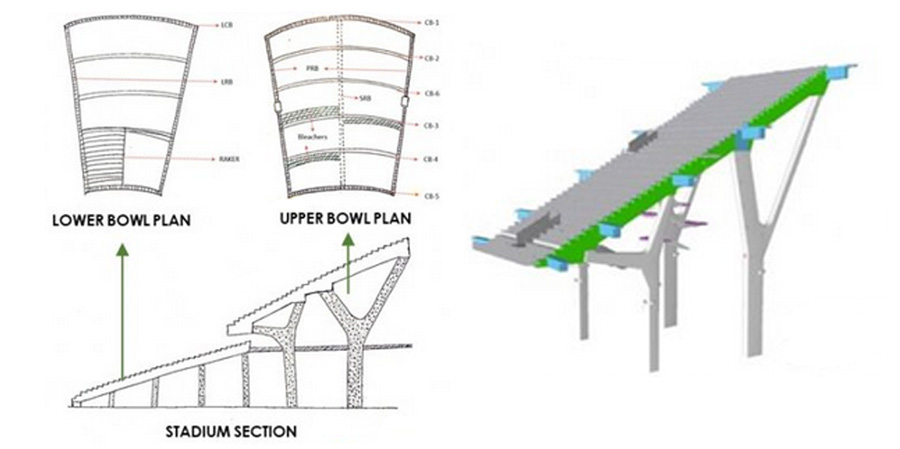

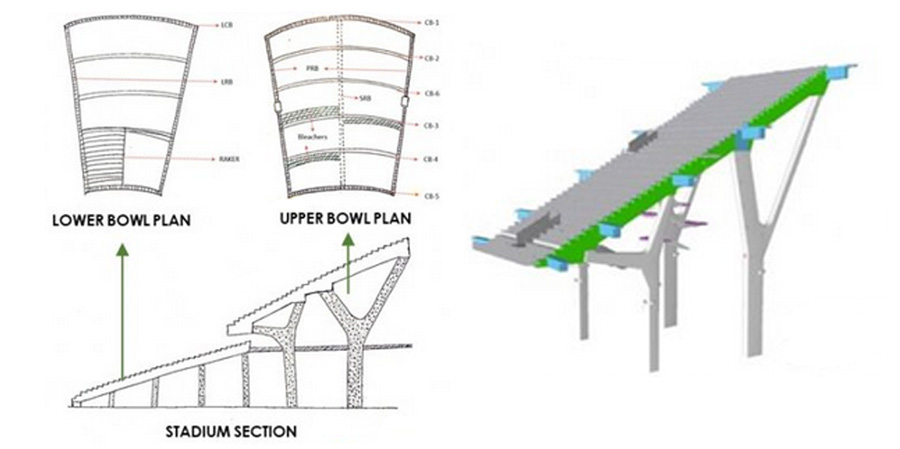

A concept of tensile fabric roof was designed by Populous for the upper bowl. Walter P Moore was the structural engineer for the roof system of the stadium. The city of Ahmedabad is located in a level 3 seismic zone because of which the roof had to be lightweight to reduce seismic demand and develop an economical roof system. The tensile fabric roof system is seismically separate from the concrete seating bowl and supported by steel “V” shaped columns. These columns were made to resist gravity and lateral loads that result from high winds and earthquakes.

The three-tier system of the design made it crucial for the roof system to be designed accordingly. All the tiers are structurally independent, which is created with the idea that the location of the stadium is at a level three seismic zone. The roof design had to be made light in weight and had to be created separately from the bowl.

Moore suggested a flexible compression system which made the erection process easier while cutting cost as well. The PTFE, woven fiberglass that was Teflon-coated, was extended in between a peripheral inner tension ring and an outer compression ring. The ring was made to float in the middle of the bowl and roof through cable spokes. This allowed movement in case of any seismic activity.

Viral Patel, who is the Director of Design working at Walter P Moore explained that the seismic forces are proportional to the mass of the structure. Because of which it was decided in the initial phase itself that incorporating a lightweight structure with a cable tensile roof would be the best decision. They also decided on keeping the roof system and the concrete bowl two free of each other.

Design head of L&T construction, Mr. R Eswaran said

“We always challenge our engineering capabilities, by strategizing to develop unique designs that perform well when executed and thereby contribute to the world of engineering by adopting the latest technologies. The Motera Stadium is one of those. Our Engineering and Execution teams are constantly in coordination to perform these big tasks. We value teamwork and success. This project is our tribute to the nation, and we are proud to contribute somehow.”

Double Curve Facade

The three-dimensional profile of the facade was of a complicated manner. That was progressed with the use of advanced software. The frame of the back is created with bent steel tubes to 3D profile, and the exterior surface is divided into parts made of aluminum sheets that are bent to profile with computerized cutting machinery.

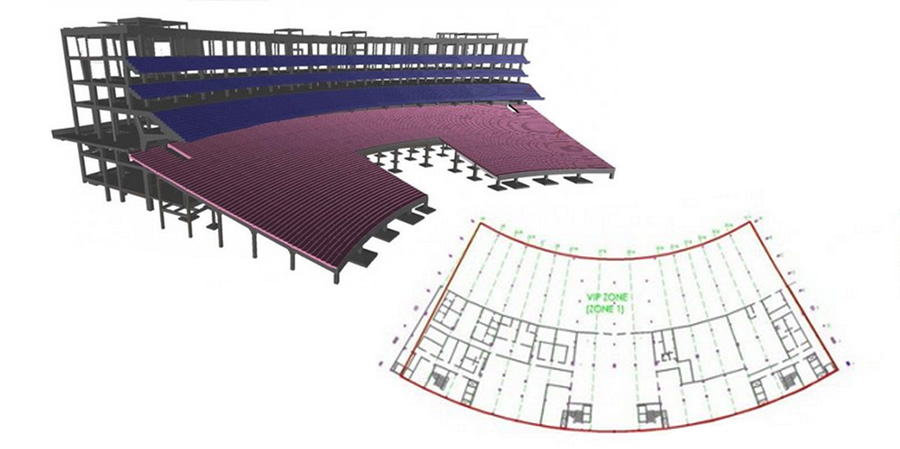

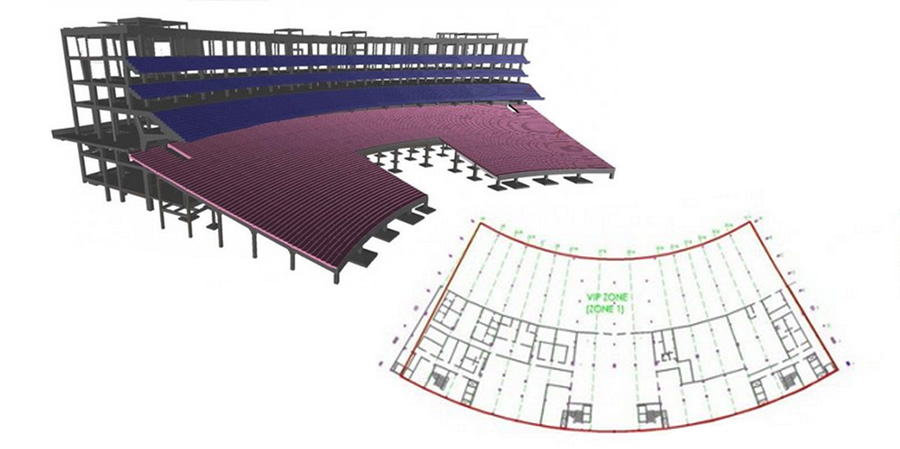

Precast segments

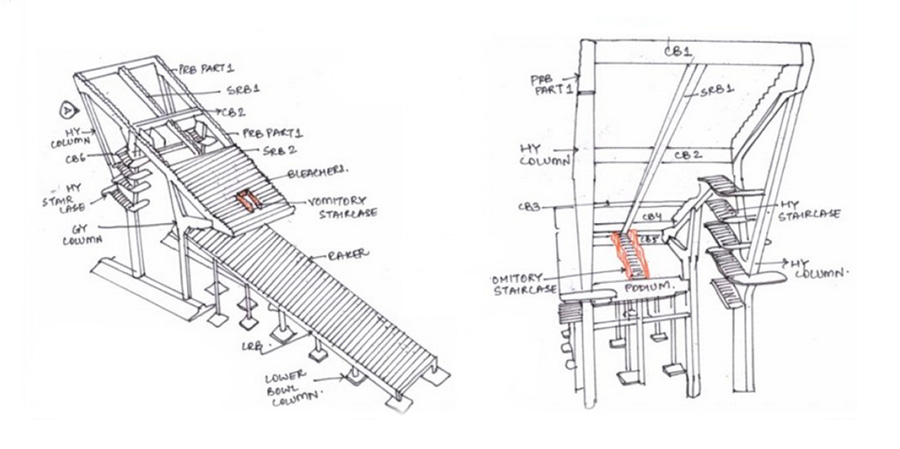

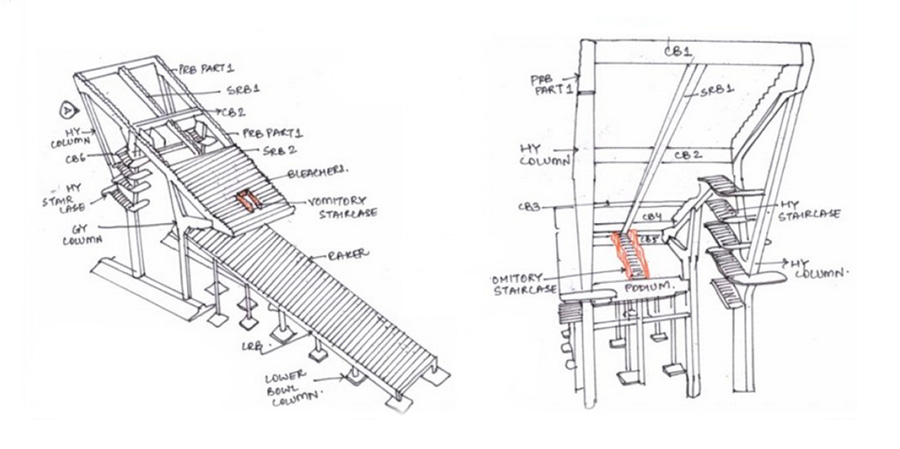

The creation of the upper bowl was the most complex part of designing the stadium. It consisted of geometric shape columns. Precast components of 35m and 285 MT in weight were used in this which helps in decreasing the joint numbers. This was also done to speed up the construction process.

Mr. Amol Acharya, the director of structural engineering of India, Walter Moore told in an interview that

“The concrete bowl structure had expansion joints while the roof structures do not contain such joints because of its nature. A combined interaction, inspection, and behavior of such structures are extremely intricate. This issue has been solved by having a separate structural system for both. This strategy also led different independent teams to work independently on two separate structures at the same time in order to meet an extremely limited project schedule.”

The senior executive vice-chairman M V Satish said

“In terms of engineering, it has been one of our most challenging projects that constituted erection of 9,000+ precast elements, that consisted of few of the heaviest weighing elements till 285 MT. For me, it has been a success of L&T in doing the things that made us proud as a nation and the teamwork that is reflected in work.”

Design concept of the stadium

The entire stadium is created section-wise by brainstorming the design of each section. A sectional view of each zone is created for better planning. There are different views of the stadium like the zone-wise division of the stadium, stadium section consisting of lower bowl plan and upper bowl plan, sectional view of the VIP zone, and other such divisions.

Other Concepts Renderings

Constructional methodology of the project

The precast methodology is being used for the construction of the project. The structural part of the construction took place in eight different phases. All the technicalities were taken care of in the progression of each phase. The positioning was decided and done for the same.

Different erection materials were erected separately. This was divided into three parts, upper bowl elements, lower bowl elements, and the connection between both.

Challenges and issues

The foremost challenge was with the roof. The roof which is made of steel was supposed to be executed with minimum tolerance for its analytical and design needs. Another thing was the erection of the steel compression ring and the pulling and locking of lock cables during the different stages. The laying of the fabric subsequently according to the requirement and its collaboration with its stakeholders was a challenging aspect. Lifting of the complex shape, heavy weight ‘Y’ column was a crucial and tough task of the precast element.

What are the challenges faced in the entire reconstruction of an existing stadium?

- The most challenging task was to turn the existing 35,000 capacity stadium into one with a seating capacity of around 110,000 people. The construction started with creating an elliptical shape stadium with detailed architectural design and structure. Keeping in mind the huge scale of the project and speed of construction, precast technology was used for the construction.

What is the technology used for completing this huge project in time?

- The whole stadium has unequally shaped ‘Y’ columns of 2.7m length, 30m height, and 285 tonnes from a single precast. They were transferred and erected on the project site. For the proper execution of the fabric design, steel structure, and cables, PTFE fabric and pre-stressed cable was used in the structural steel roof.

- The roof is 1000m in perimeter, 10.5m height truss, 30m cantilever, and an elevation of 40m above ground level. The whole planning was itself a challenge considering the location of the site which had several residential complexes around it. The execution, transportation of materials and machinery was a tremendous task.

What were the architectural references used in the designing process?

- The stadium was inspired by the Melbourne Cricket stadium. The goal was not only to make the largest stadium but was also to meet up to the standard of that one. The features of it, size and facilities everything had to be at par. To give an excellent visual experience for the spectators, a 360° view was a key need.

For such kinds of huge projects, the most important thing to have is a great team having a high vision, zeal, and passion in CAD Drafting and BIM Modeling for bringing high-quality work to the table. Archdraw Outsourcing is one of the leading names in the architectural business. We work on high-scale projects by producing services related to drafting, modeling, and rendering. We are an experienced outsourcing firm, with skilled and enthusiastic personnel putting their mind at quality work. We are proficient in working on complex projects as well. We have worked on different constructional ideas such as skyscrapers, hospitals, educational institutes, airports, stadiums, and much more. Our expertise in the field can be measured with the standard of services we have been providing over the years.

Thank you for sharing this information with us. Really appreciate your efforts.